Ideal GDM Double Cartridge Mechanical Seal for Goulds 3196 Chemical Process Pumps

GDM Standard Stationary Double Seal Solution for Higher Effeicent OEM Customers

Operation Parameters:

• Temperature: -20 ~ 220ºC

• Pressure: 0-25Bar

• Linear Speed: up to 25m/s

• Sealing Product: Acid, alkaline, low percentage of pulp, water, oil and other similar medi

Materials:

• Seal Face: SSIC/TC/CARBON

• Rubber: EPDM/ FKM /Aflas/ Kalrez

• Springs: ALLOY276

• Metal Parts: 316SS/DUPLEX/ALLOY276/904L

Key Features:

• Stationary face compensation technology.

• Solid seal structure reduces deformation at high temperature and low temperature conditions.

• Intergrated and Bi-directional diversion, sleeve with pump ring.

• High speed limits, up to 220 degree. No seal face drop or displacement.

• Higher pressure limits, up to 25 bar.

• Wet Part in Duplex steel, 904L, Alloy 276 avaiable.

• Suitable for API Plan 52/53A/53B/54.

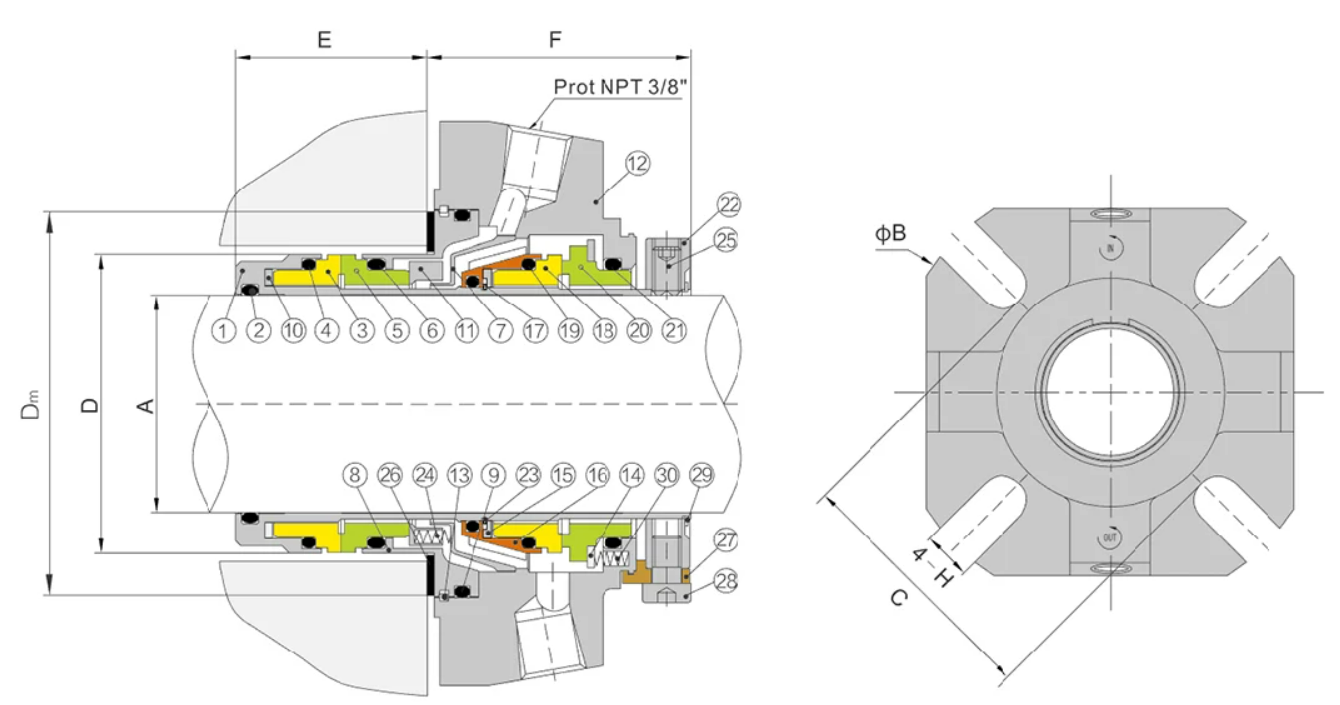

|

NO |

Decription |

Material |

NO |

Decription |

Material |

|

1 |

Shaft Sleeve |

316SS |

16 |

Pump Ring |

316SS |

|

2 |

O-Ring |

EPR/FKM/Aflas/Kalrez |

17 |

O-Ring |

EPR/FKM/Aflas/Kalrez |

|

3 |

Inboard Rotary Face |

SSIC/TC |

18 |

Outboard Rotary Face |

SSIC/TC |

|

4 |

O-Ring |

EPR/FKM/Aflas/Kalrez |

19 |

O-Ring |

EPR/FKM/Aflas/Kalrez |

|

5 |

Inboard Stationary Face |

Carbon/SSIC/TC |

20 |

Outboard Stationary Face |

Carbon/SSIC/TC |

|

6 |

O-Ring |

EPR/FKM/Aflas/Kalrez |

21 |

O-Ring |

EPR/FKM/Aflas/Kalrez |

|

7 |

Deflector |

316SS |

22 |

Clamp Ring |

316SS |

|

8 |

Gland Insert |

316SS |

23 |

Circlip |

316SS |

|

9 |

O-Ring |

EPR/FKM/Aflas/Kalrez |

24 |

Spring |

Alloy276 |

|

10 |

Drive Ring |

316SS |

25 |

Drive Screw |

316SS |

|

11 |

Spring Plate |

316SS |

26 |

Gasket |

AF1 |

|

12 |

Gland |

316SS |

27 |

Setting Clip |

Brass |

|

13 |

Snap Ring |

316SS |

28 |

Clip Screw |

316SS |

|

14 |

Spring Plate |

316SS |

29 |

Circlip |

316SS |

|

15 |

Pin |

316SS |

30 |

Spring |

Alloy276 |

|

φA |

φB |

C |

φD |

φDm |

E |

F |

H |

|

25 |

105 |

66.5 |

42.0 |

55.0 |

38.9 |

54.2 |

14 |

|

28 |

105 |

66.5 |

45.5 |

60.0 |

38.9 |

54.2 |

14 |

|

30 |

105 |

66.5 |

47.0 |

60.0 |

38.9 |

54.2 |

14 |

|

32 |

105 |

66.5 |

50.0 |

63.0 |

38.9 |

54.2 |

14 |

|

33 |

105 |

66.5 |

50.0 |

63.0 |

38.9 |

54.2 |

14 |

|

35 |

120 |

68.5 |

52.0 |

65.0 |

38.9 |

54.2 |

14 |

|

38 |

135 |

80 |

55.0 |

75.5 |

40.1 |

54.2 |

15 |

|

40 |

135 |

80 |

57.0 |

75.5 |

40.1 |

54.2 |

15 |

|

43 |

135 |

80 |

60.0 |

75.5 |

40.1 |

54.2 |

15 |

|

45 |

139 |

84.5 |

62.0 |

80.0 |

40.1 |

54.2 |

14 |

|

48 |

139 |

84.5 |

65.0 |

80.0 |

40.1 |

54.2 |

14 |

|

50 |

150 |

87.5 |

68.0 |

83.0 |

40.1 |

54.2 |

17.5 |

|

53 |

150 |

97 |

72.0 |

93.0 |

40.1 |

54.2 |

17.5 |

|

55 |

150 |

97 |

72.0 |

93.0 |

40.1 |

54.2 |

17.5 |

|

60 |

165 |

102 |

77.9 |

98.5 |

40.1 |

54.2 |

17.5 |

|

63 |

171 |

108 |

81.0 |

104.5 |

40.1 |

54.2 |

17.5 |

|

65 |

171 |

108 |

84.2 |

104.5 |

40.1 |

54.2 |

17.5 |

|

70 |

180 |

112 |

87.5 |

107.0 |

40.1 |

54.2 |

17.5 |

Remarks: The below mentioned part number is used for helping our customer fast confirmation only. We are not authorized to use these part numbers on any of our pump parts.

BETTER Drilling Fluid Solution Limited

BETTER Drilling Fluid Solution Limited